It is in your interest to understand the use and care of

your radon reduction system. It needs little maintenance, but there are

some things to be aware of. Periodcally confirm that your fan runs. If

it doesn't, contact us to have it replaced. Any updates to your home

should be made in a radon-safe manner. If you have any questions or

concerns, please email us anytime or call between 9:00 AM and 5:00 PM.

Radon systems are

simple in principle.

They work by moving unwanted soil gases from under the slab into a vent

pipe. Most problems are because not enough air is flowing, or because

air is flowing but not from the right area under the slab.

|

|

Radon

fan

Because radon continually rises from the earth, the vent fan runs constantly to

extract it. Observe the U-tube

at least quarterly.

Dead fans should usually be replaced with another of the same

model. A different model may be used on the advice of a qualified

professional.

A fan is just one part of a radon system. Proper design and

installation is needed to get good results. Only an accurate radon

measurement can prove its effectivness.

Typical electrical cost is well under $10/month. We can help you

calculate the consumption in terms of kilowatt-hours.

Fans that are wearing out tend to get louder or make

intermittent noises, but may still do their jobs. We can replace any

fan that eventually fails or becomes annoying.

|

|

Checking this gauge is your most

important job as a radon system owner. It tells you if the fan

is running.

Displays pressure difference between each side of the tube - one

inside the pipe, the other in open air. Normally on the basement pipe.

On the left, U-tube shows the fan working well. There is a difference in pressure.

In the center, U-tube shows "0-0".

Sides equal. The fan is not running.

If you see "0-0", make

sure the flexible hose is connected between the U-tube and pipe. On the

right, our fan is running but the hose is disconnected.

Rarely, U-tubes get stuck and falsely indicate a pressure

difference. If you remove the flexible hose from the pipe, the two

sides should immediately equalize. If they don't, it's stuck. Easily

fixed by tapping it or very gently blowing into the hose until the

fluid moves.

On passive vent with no fan, there is usually no U-tube.

|

|

Power

A non-running fan could be dead, or it may be unpowered. Ensure

it's plugged in or its switch is turned on. Check any GFI devices or

breakers connected to the same circuit as the fan.

|

|

Rubber

couplers

The fan

and any radon pipe to a sump pit are connected with rubber couplers.

These are provided for service. The hose clamps are loosened or

tightened with a large flathead screwdriver or a 5/16" hex. Once

loosened, couplers can slide down the pipe.

The seal of a roof flashing or airtight sump lid may be compromised by

interacting with these couplers! Do not adjust them unless you have a

good reason. They offer quick access in case your sump pit is filling.

|

|

Sealed

sump lid

Sump

pits must

be airtight

for radon systems to work properly, even systems that are not directly

connected to the sump pit.

Bolt-down gasket type lids are common. If needed, we custom make clear

plastic

lids cut to fit your existing sump system then seal the edges with

silicone sealant.

When the

seal is broken, it must be restored to airtight condition.

If a radon pipe goes into the sump pit, remove it first before

taking off the lid.

Silicone is easy to cut with a razor knife or flathead screwdriver.

Some of our lids are cut to flex around the pump pipe. There is no

danger of them breaking if you flex them. Others slide up the pump pipe.

|

|

Other

leaks in slab or foundation wall

Relevant leaks will be dealt with at the time of radon system

installation. In time, new leaks can appear by age, damage, or

modifications to the building.

The joint between basement slab and foundation wall could

expand. New cracks could form in the slab or foundation wall. Backflow

valves in floor drains may get stuck open. New holes for plumbing, etc

must be patched up.

Interior perimeter drains can cause massive leaks. If you get one or

plan on getting one and you also have a radon system, please contact us.

|

|

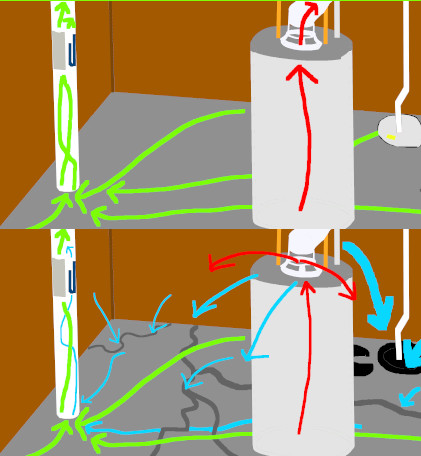

Backdrafting

of combustion appliances

Not a concern with newer forced-air appliances.

If a radon system causes strong enough draft, it may cause exhuast

gases from older naturally-vented appliances to backflow into the

building envelope rather than into the vent hood. This could result in carbon monoxide exposure.

If necessary, we test for backdrafting during installation. It

doesn't hurt to check every few years and to have a carbon monoxide

alarm installed near these appliances.

Top: Proper installation

Bottom: Poor performance and potential hazard due to leaks.

|

|

Ice

The air flowing through radon vents has high moisture content. On the

very coldest winter days, ice can form on the tip of the vent. Normally

this doesn't obstruct the vent and melts away as soon as it warms up.

If ice does obstruct the pipe for a long time, it can be removed. It's

best to turn off the fan and wait for it to stop spinning first. Ice

can be prevented from falling into the fan by removing the top of the

vent from the rubber coupler.

We're sometimes asked why our vents don't have rain caps or

critter guards. It's because ice forms on those so easily. In

Wisconsin, they'd cause much more trouble than they'd solve.

|

|

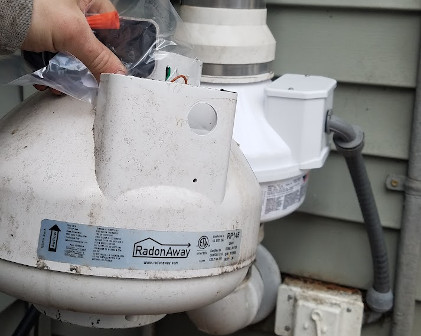

Fan

cleaning

Most radon fans never need any cleaning, but the only way to tell if

one does is to inspect it physically. Some buildings have so many bugs

under the slab that they get sucked in and build up a layer of gunk on

the fan, which causes noisier operation and a shorter service life.

While the fan can work for a while in this condition, it really should

be cleaned.

We offer a regular cleaning service, but this is also something you

might do for yourself, especially with exterior systems. The fan is turned

off and disconnected from pipe for inspection or cleaning. |

|

|